The graphene problem - why biosensor manufacturers are yet to successfully leverage graphene"

class="w-full h-full object-cover"

/>

The graphene problem - why biosensor manufacturers are yet to successfully leverage graphene"

class="w-full h-full object-cover"

/>

The graphene problem - why biosensor manufacturers are yet to successfully leverage graphene

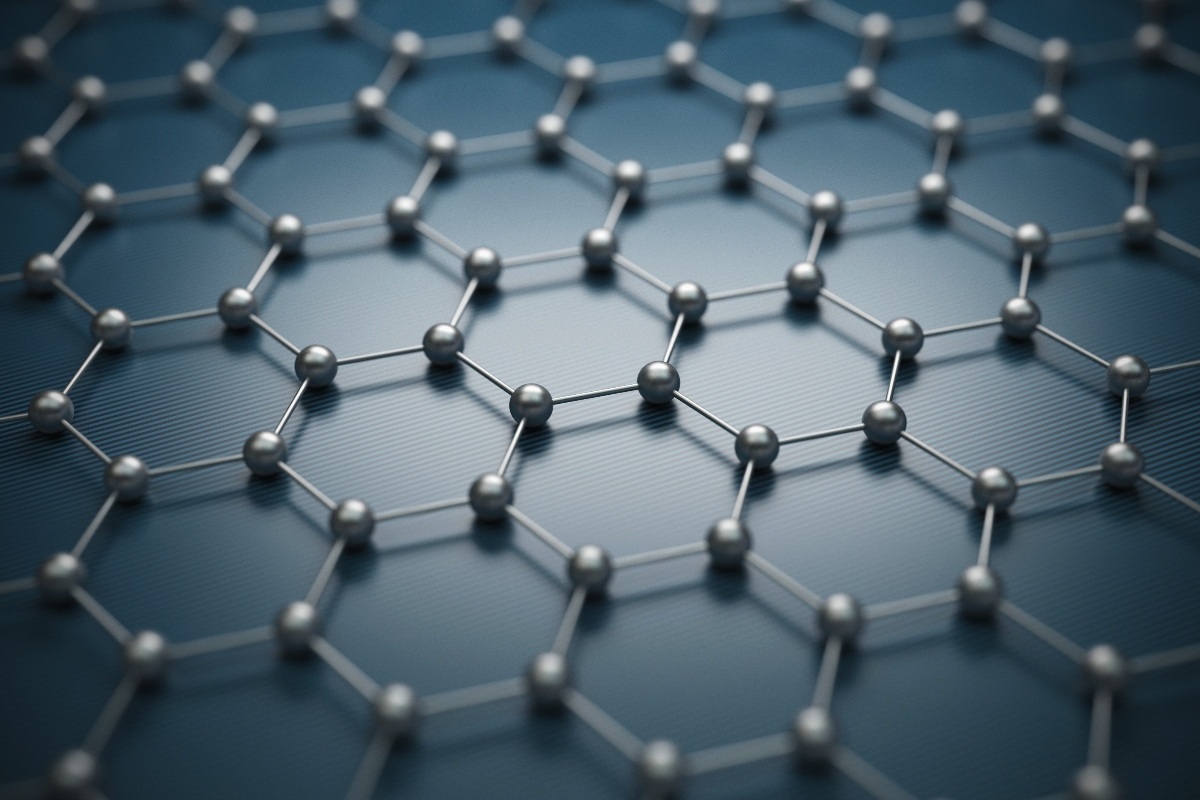

Graphene’s discovery sparked widespread enthusiasm in materials science, heralded as a game-changer for everything from electronics to biomedical diagnostics. With its remarkable electrical conductivity, large surface area, mechanical strength and biocompatibility, graphene seemed destined to change electrochemical biosensors for the better.

Yet, more than a decade on, commercial biosensor applications using the material remain limited. The gap between graphene’s laboratory promise and real-world deployment is not due to a lack of interest, but a consequence of deep-rooted technical and manufacturing barriers. Fortunately, new innovations in carbon-based nanomaterials are set to fill the role of graphene in biosensing and other applications moving forward.

The scaling challenge - high costs and low yield

One of the most persistent obstacles to mainstream graphene adoption is cost-effective scalability. High-quality monolayer or few-layer graphene, typically synthesised via chemical vapour deposition (CVD), is costly to produce at commercial volumes. Even exfoliation methods which are potentially more scalable result in heterogeneous materials, where flake size, thickness and functional group content vary dramatically from batch to batch.

This batch-to-batch variability significantly impacts sensor reproducibility and reliability, particularly when consistent electrochemical performance is needed across clinical diagnostics. For biosensors where sensitivity and selectivity hinge on controlled surface chemistry and electronic properties, these inconsistencies undermine commercial viability.Functionalisation and integration - a delicate trade off

In principle, graphene provides an ideal transduction platform for biosensors due to its high conductivity. This is thanks to its structure, which is a single layer of sp²-hybridised carbon atoms arranged in 2D crystal honeycomb lattice. However, translating that conductivity into practical biochemical detection requires functionalisation, which is immobilising recognition elements (e.g. antibodies, enzymes, aptamers) onto the graphene surface.

Here lies another challenge with graphene. Whilst covalent functionalisation ensures strong, stable binding, it disrupts the sp² lattice, degrading graphene's electrical performance. Non-covalent approaches better preserve conductivity but often lack robustness in physiological environments. This delicate trade-off between preserving graphene’s structure and achieving biofunctionality has limited the real-world reliability of graphene-based biosensors.Performance consistency - a commercial bottleneck

Even when functionalisation is achieved, integrating graphene into device architectures that can be mass-produced with tight tolerances is a major engineering hurdle. Three key challenges emerge which result in high R&D costs, low device yields and limited confidence from commercial stakeholders.

- Reproducibility: Even minor variations in surface chemistry can drastically alter electron transfer kinetics, affecting limit of detection and specificity.

- Environmental sensitivity: Graphene’s properties are highly responsive to surface adsorbates, humidity and pH, making calibration and shelf-life problematic.

- Biofouling: In real biological fluids (saliva, blood, urine), non-specific protein adsorption can mask or distort signals, limiting application in point-of-care settings.

Overcoming the drawbacks of graphene with new carbon-based nanomaterials

Recognising the limitations of conventional graphene, researchers have turned to next-generation carbon-based nanomaterials specifically engineered for biosensing. These materials depart from the traditional 2D paradigm, embracing three-dimensional, porous architectures that enhance electrochemical responsiveness whilst addressing longstanding issues of scalability and reproducibility.

- Scalability and cost: These materials enable reproducible manufacture at scale without transfer steps or high-temperature synthesis, reducing production costs.

- Functionalisation versatility: These materials can be modified without damaging their structure, using chemical interactions that maintain high conductivity whilst allowing biomolecules to attach securely.

- Enhanced performance: The high surface area and architecture of these materials promote efficient analyte capture and rapid electron transfer to enhance performance and sensitivity.

- Integration-ready: Devices fabricated with these materials are compatible with microfluidic architectures, enabling plug-and-play integration into lab-on-chip platforms.

- Anti-fouling properties: The surface properties of these materials help resist non-specific adsorption of proteins and other contaminants, improving stability and performance in complex biological samples like saliva, blood or serum.

Integrate a biosensor material of the future

The promise of graphene in biosensors has long been clear, but so too have its limitations. For years, the field has wrestled with the challenge of transforming an exceptional material into a commercially viable sensing platform. Today, that transformation is being realised through Gii, a next-generation carbon nanomaterial purpose-built for electrochemical biosensing.

By addressing the critical barriers of scalability, functionalisation, and performance stability, Gii enables the development of cost-effective, high-sensitivity sensors that can operate reliably in real biological environments. Its engineered structure, compatibility with flexible platforms, and resistance to biofouling position it as a leading candidate for point-of-care diagnostics across healthcare, wellness, and research settings.

In short, Gii offers what conventional graphene could not: a clear path from materials science to real-world impact.